Peralatan dan material utama dari proyek sistem pemantauan proses elektrolisis timbal meliputi kamera inframerah ALG3000, komputer pemantauan gambar, modul inspeksi tegangan 50 saluran, pemancar arus 4-20mA, sistem data kontrol industri, kendali jarak jauh elektrik anti-korosi serat karbon pan/tilt, dll.

Busbar tembaga untuk rekayasa elektrolisis

Busbar tembaga untuk menghubungkan pekerjaan elektrolisis

1.

Peran Busbar Tembaga dalam Rekayasa Elektrolisis

1.1 Konduktivitas:

Fungsi Utama: Busbar tembaga sangat penting dalam sistem elektrolisis karena konduktivitas listriknya yang sangat baik. Busbar ini berfungsi sebagai jalur utama untuk mengalirkan arus besar yang dibutuhkan dalam proses elektrolisis. Konduktivitas tembaga yang tinggi memastikan kehilangan daya minimal selama transmisi, yang krusial untuk menjaga efisiensi dalam operasi elektrolisis.

1.2 Distribusi Saat Ini:

Distribusi Arus yang Merata: Busbar tembaga membantu mendistribusikan arus listrik secara merata ke berbagai elektroda dalam sel elektrolisis. Distribusi yang merata ini penting untuk memastikan reaksi elektrokimia yang konsisten di semua elektroda, sehingga menghasilkan deposisi atau pelarutan material yang merata.

1.3 Dukungan Struktural:

Kekuatan Mekanis: Busbar tembaga juga memberikan dukungan struktural pada elektroda dan seluruh rangkaian elektrolisis. Busbar ini kokoh dan dapat menahan beban arus tinggi tanpa mengalami deformasi, yang membantu menjaga integritas proses elektrolisis.

1.4 Pembuangan Panas:

Manajemen Termal: Selama proses elektrolisis, sejumlah besar panas dihasilkan karena aliran arus yang tinggi. Busbar tembaga memiliki konduktivitas termal yang baik, yang membantu menghilangkan panas, sehingga mengurangi risiko panas berlebih dan meningkatkan keamanan serta umur sistem secara keseluruhan.

2.

Hal-hal yang Perlu Diperhatikan Saat Menggunakan Busbar Tembaga

2.1 Ukuran dan Penampang:

Ukuran yang Tepat: Sangat penting untuk memilih busbar tembaga dengan luas penampang yang tepat untuk menangani beban arus yang diinginkan. Busbar yang terlalu kecil dapat menyebabkan pemanasan berlebih, kehilangan energi, dan potensi kegagalan akibat tekanan termal.

2.2 Sambungan dan Sendi:

Sambungan Aman: Sambungan dan sambungan antara busbar dan komponen lainnya harus terpasang dengan aman dan bebas dari oksidasi atau kontaminan. Sambungan yang longgar atau terkorosi dapat meningkatkan resistansi, yang mengakibatkan pemanasan lokal, inefisiensi energi, dan potensi kegagalan listrik.

2.3 Perlindungan Korosi:

Oksidasi: Tembaga dapat teroksidasi saat terpapar udara, terutama di lingkungan yang lembap atau korosif. Penting untuk memastikan busbar diisolasi dengan benar atau dilapisi dengan lapisan pelindung untuk mencegah oksidasi, yang dapat menurunkan konduktivitas dan integritas struktural.

2.4 Ekspansi Termal:

Kompensasi Ekspansi: Tembaga memuai karena panas, sehingga desain sistem elektrolisis harus memperhitungkan ekspansi dan kontraksi termal. Penyesuaian ekspansi yang tidak tepat dapat menyebabkan tekanan mekanis dan ketidaksejajaran dalam sistem, yang berpotensi menyebabkan masalah operasional atau kerusakan.

2.5 Pemeliharaan:

Inspeksi Rutin: Perawatan dan inspeksi berkala sangat penting untuk memastikan busbar tembaga tetap dalam kondisi baik. Ini termasuk memeriksa tanda-tanda korosi, sambungan longgar, dan kerusakan fisik apa pun yang dapat memengaruhi kinerja.

2.6 Isolasi Listrik:

Tindakan Pengamanan: Meskipun tembaga merupakan konduktor yang sangat baik, sama pentingnya untuk memastikan bahwa tembaga diisolasi dengan benar bila diperlukan untuk mencegah terjadinya korsleting yang tidak disengaja dan memastikan pengoperasian yang aman dalam pabrik elektrolisis.

Dengan memperhatikan faktor-faktor ini dengan saksama, busbar tembaga dapat meningkatkan efisiensi, keandalan, dan keamanan sistem elektrolisis secara signifikan. Desain, pemasangan, dan perawatan yang tepat merupakan kunci untuk memaksimalkan manfaat busbar tembaga dalam aplikasi arus tinggi tersebut.

Peralatan dan aksesori elektrolisis lainnya

Peralatan bantu rekayasa elektrolisis timbal

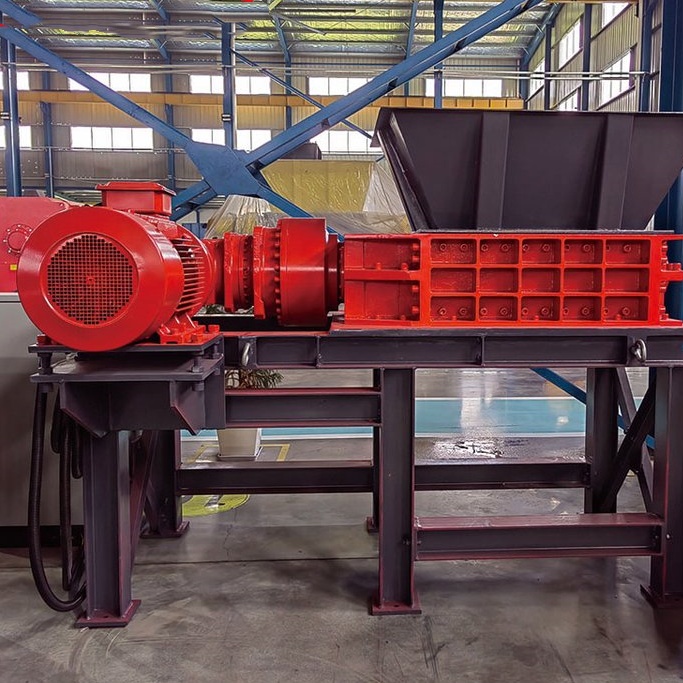

Mesin terak timbal elektrolitik

Mesin Batang Cahaya Elektrolisis Timbal

3. Rectification wiring method: 2 three-phase full-controlled bridges in parallel

4. Voltage regulation method: primary on-load voltage regulation + secondary thyristor voltage

regulation

5. Cooling method: transformer forced oil cooling, rectifier cabinet pure water cooling

6. Inlet and outlet method: transformer top outlet. Rectifier cabinet top inlet and bottom outlet

Production workshop

Installation site

Silicon controlled rectifier products

Rectifier transformer

High frequency switch rectifier cabinet for electrolysis

IGBT rectifier cabinet for electrolysis

HHF16000A80V high-frequency switch rectifier power cabinet adopts a distributed control power system, with 32 power modules connected in parallel to achieve the output of 16000A80V rated current and voltage.

1. The main circuit of the single power module adopts advanced full-range soft switching technology, with high reliability, low loss, and working efficiency of more than 90%;

2. The single module adopts small and medium power (500A80V), which makes the system stability and flexibility extremely high.

3. It has automatic protection alarm functions such as overvoltage, overcurrent, overtemperature, and phase loss, as well as soft start function.

The whole machine is made with a full range of anti-corrosion technology, which enhances the product's anti-corrosion ability and prolongs its service life.

HHF16000A80V Technical parameters of the power supply system

4. Control motherboard: The control motherboard adopts the latest fully digital boxed modular

motherboard, which is maintenance-free.

5. Control system: Conventional control has constant current and constant voltage control

systems. Under the conditions of 5~100% rated output current and 10~100% rated output voltage, the automatic current and voltage control device ensures that the DC current is constant at ±1.0%. This equipment adds a constant process parameter working control mode. There are process parameter settings (-2.00~2.00V) and feedback signal display (-2.00~2.00V) on the touch screen.

6. The electrolytic power supply device is an indoor cabinet structure, and the shell protection level is IP20 and above

Intelligent lead electrolysis process centralized control equipment

Lead electrolysis process centralized as soon as possible system

The lead electrolytic cell surface management process monitoring system uses a number of national patent technologies such as cell surface infrared imaging temperature measurement, partition positioning, fuzzy intelligent judgment, cell voltage inspection, current effect analysis, and DC power consumption management to comprehensively manage the electrolytic process quality of the lead electrolytic cell surface. The cell surface infrared imaging temperature measurement uses imported high-performance infrared imagers and our company's special image partition positioning software to perform partition positioning and temperature management of each pixel on the cell surface, and compares and judges whether the temperature of each pixel is too low, normal, too high, or too high. At the same time, the actual working conditions, abnormal conditions, and accident events of each point temperature, cell voltage, and current are recorded and analyzed, and a work daily report is directly generated. Reliable data and reports are provided for production management, energy saving and production increase, and process management.

The main equipment and materials of the lead electrolysis process monitoring system project include infrared camera ALG3000, image monitoring computer, 50-channel voltage inspection module, 4-20mA current transmitter, industrial control data system, carbon fiber anti-corrosion electric remote control pan/tilt, etc.

Infrared imaging analysis of the lead electrolysis process tank surface

Copper busbar for electrolysis engineering

Copper busbars for connecting electrolysis works

1. The Role of Copper Busbars in Electrolysis Engineering

1.1 Conductivity:

Primary Function: Copper busbars are critical in electrolysis systems due to their excellent electrical conductivity. They serve as the main pathways for conducting the large currents required in electrolysis processes. The high conductivity of copper ensures minimal power loss during transmission, which is crucial for maintaining efficiency in electrolysis operations.

1.2 Current Distribution:

Uniform Current Distribution: Copper busbars help distribute electrical current evenly across multiple electrodes within the electrolysis cell. This uniform distribution is essential to ensure consistent electrochemical reactions across all electrodes, leading to uniform deposition or dissolution of materials.

1.3 Structural Support:

Mechanical Strength: Copper busbars also provide structural support to the electrodes and the entire electrolysis setup. They are robust and can support the heavy current loads without deforming, which helps maintain the integrity of the electrolysis process.

1.4 Heat Dissipation:

Thermal Management: During the electrolysis process, significant amounts of heat are generated due to high current flow. Copper busbars have good thermal conductivity, which helps in dissipating heat, thereby reducing the risk of overheating and improving the overall safety and longevity of the system.

2. Matters Needing Attention When Using Copper Busbars

2.1 Size and Cross-Section:

Proper Sizing: It is essential to select copper busbars with the correct cross-sectional area to handle the intended current load. Undersized busbars can lead to excessive heating, energy losses, and potential failure due to thermal stress.

2.2 Connections and Joints:

Secure Connections: The joints and connections between busbars and other components must be securely fastened and free of oxidation or contaminants. Loose or corroded connections can increase resistance, leading to localized heating, energy inefficiency, and potential electrical failures.

2.3 Corrosion Protection:

Oxidation: Copper can oxidize when exposed to air, particularly in humid or corrosive environments. It's important to ensure that the busbars are either properly insulated or treated with protective coatings to prevent oxidation, which can degrade conductivity and structural integrity.

2.4 Thermal Expansion:

Compensating for Expansion: Copper expands with heat, so the design of the electrolysis system must account for thermal expansion and contraction. Improper allowances for expansion can lead to mechanical stresses and misalignment in the system, potentially leading to operational issues or damage.

2.5 Maintenance:

Regular Inspections: Periodic maintenance and inspections are crucial to ensure that the copper busbars remain in good condition. This includes checking for signs of corrosion, loose connections, and any physical damage that could affect performance.

2.6 Electrical Insulation:

Safety Measures: While copper is an excellent conductor, it is equally important to ensure that it is properly insulated where necessary to prevent accidental short circuits and ensure safe operation within the electrolysis plant.

By paying close attention to these factors, copper busbars can significantly enhance the efficiency, reliability, and safety of electrolysis systems. Proper design, installation, and maintenance are key to maximizing the benefits of copper busbars in such high-current applications.

Other electrolysis equipment and accessories

Lead electrolysis engineering auxiliary equipment

Electrolytic lead slag machine

Lead Electrolysis Light Rod Machine

Analisis pencitraan inframerah pada permukaan tangki proses elektrolisis timbal